Dropping the ballast

Ballast dropped to allow access for repairs and replacement of fastenings

Winter 2012-13, Cockwells Boatbuilding, Mylor Bridge

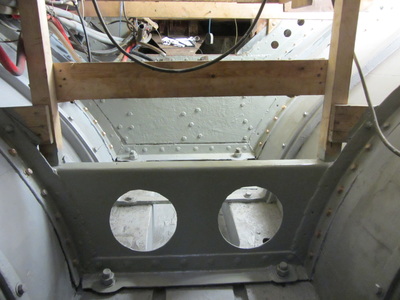

Sceptre was taken to Cockwells Boatbuilding near Falmouth in November 2012 for some major repairs, including the replacement of the floor fastenings in the area above the ballast. To access these bolts however, meant that the 17 ton lead ballast had to be dropped, an operation which went surprisingly smoothly considering the age and weight of the boat. Other works included the replacement of a number of timber frames, repairs to some damaged planking and a long list of other more routine tasks.

Top row: Sceptre was lifted into Cockwells' floating dry dock for the trip from Falmouth to Mylor Bridge

Bottom Row: Sceptre being refloated from the floating dry dock (photos by Cockwells Boatbuilding)

Bottom Row: Sceptre being refloated from the floating dry dock (photos by Cockwells Boatbuilding)

The 17 ton lead ballast was separated from the keel for the first time in over 50 years (photos by Cockwells Boatbuilding)

|

The scope of work for Sceptre's refit at Cockwells included:

1. Lift boat from ballast 2. Check and refit all floor fastenings 3. Replace 18 throat bolts 4. Remove and replace port garboard 5. Re-fasten, clean and paint 11 frames 6. Laminate and fit 7 new timber frames 7. Grit blast and paint 5 strap floors 8. Refit ballast 9. Caulk and spline 10. Replace sheathing 11. Make good internal fit-out |